Sanitary Rotary Lobe Pumps

sanitary and hygienic rotary lobe and external circumferential piston pumps.

Rotary lobe pumps are widely used in hygienic applications such as food and beverage processing, pharmaceuticals, and cosmetics due to their ability to handle a wide range of fluids with care and precision. These positive displacement pumps are known for their gentle product handling, versatility, and high standards of cleanliness, making them ideal for industries where contamination control is critical.

Our ranges of Waukesha pumps are for use in the production of food and berevages. They are fully hygienic and ideal for use in dairies and prepared food applications. They offer 3-A, EHEDG and comply with EC 1935/2004. Rotary lobe pumps make ideal sanitary pumps as they offer a gentle low shear pumping action, the ability to handle solids and viscous products.

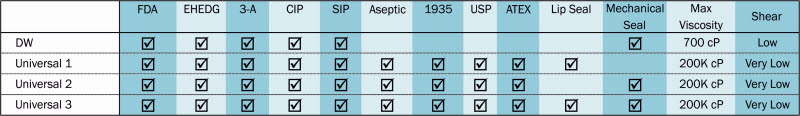

We have four main ranges of food grade pumps in this category. The MDL is simple hygeinic tri-lobe pump while the Universal I, Universal II and Universal 420/520 are all circumferential piston (ECP) pumps. They are all sanitary pumps and can pump up to 190 m3/hour.

Hygienic Design

- Smooth Internal Surfaces: Rotary lobe pumps are built with highly polished stainless steel interiors (usually 316L) to reduce the risk of product contamination and bacterial growth. This makes them easy to clean and compliant with strict sanitary standards like FDA and EHEDG.

- Sanitary Seals: These pumps are equipped with food-grade seals (such as EPDM, FKM, or PTFE) that prevent leaks and contamination, ensuring the product remains pure throughout the pumping process.

- Minimal Contact with Pump Housing: The lobes do not make direct contact with each other or the pump housing, reducing wear and ensuring smooth, consistent operation while maintaining hygienic conditions.

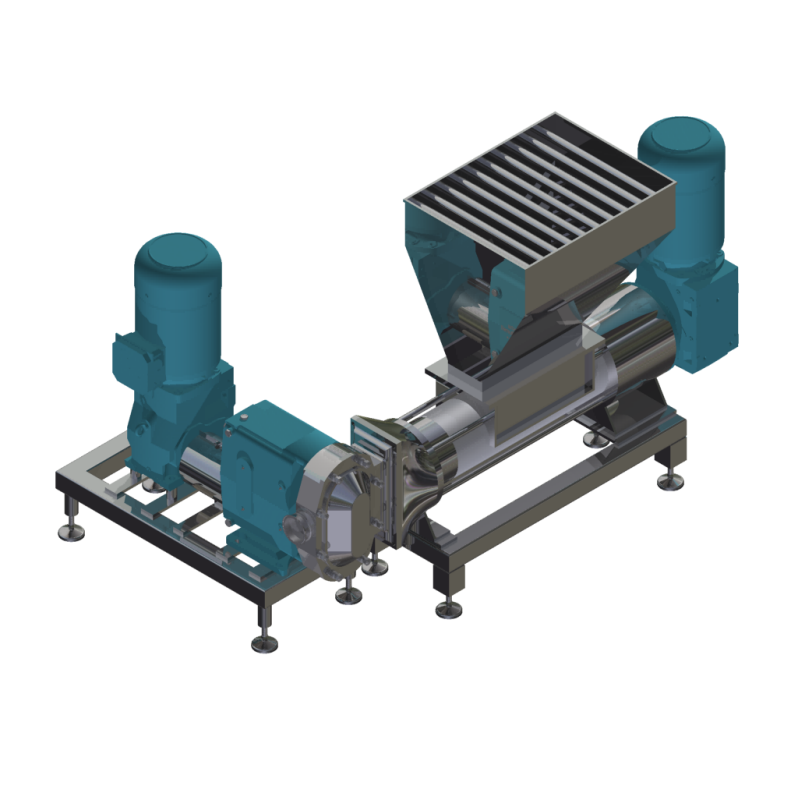

Auger Systems for high viscosity products

Benefits of hygienic rotary lobe pumps

- Hygienic Compliance: Rotary lobe pumps meet the highest hygiene standards, including FDA, 3A, and EHEDG certifications, ensuring they are suitable for food, pharmaceutical, and cosmetic applications.

- Product Integrity: Gentle product handling and minimal shear forces preserve the texture, flavor, and quality of sensitive products.

- Operational Flexibility: Capable of handling a wide range of fluid viscosities, solid content, and operating conditions, rotary lobe pumps are highly adaptable to various processes and fluid types.

Things to Consider when selecting hygienic Lobe pumps

- Fluid Characteristics: Understanding the viscosity, temperature, and particulate content of the fluid is essential for selecting the right rotary lobe pump configuration.

- Sanitary Standards: Ensure that the pump's materials, seals, and design comply with relevant sanitary standards for your specific industry, such as FDA or 3A certification.

- Flow Rate and Pressure: Rotary lobe pumps offer variable flow rates and high-pressure capabilities, so it's important to match the pump's capacity to your operational requirements.