There are many challenges when pumping hot liquids. Cavitation can occur if the liquid is too near its boiling point unless there is enough pressure applied to stop this. Flashing at the seal face can be a problem when pumping hot liquids so cooling and pump designs that ensure a higher pressure around the seal should be used.

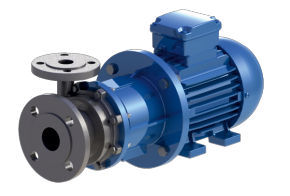

Magnetic drive and canned pumps usually offer the safest and most reliable option for hot liquid applications as they contain the liquid while avoiding the problems of seal flashing.

When it comes to pumping cold liquids the problems can be surprisingly similar to hot liquids. Cavitation is often a problem due to the thin and very low boiling points of many refrigerants. Lubrication can be a problem and off gas if pumps with mechanical seals are used.

Specific thermal service applications:

Our Wilden AOD pumps offer a cost effective and proven solution to pump liquids up to 176 oC, while our Almatec pumps over very high levels of product containment.

Or centrifugal pump portfolio contains many ranges suitable for use as high temperature pumps. This includes magnetic drive pumps, ISO pumps, canned pumps we can pump liquids with temperatures up to 450 oC.

Our range of ECP pumps from Waukesha can handle liquids up to 176 oC.

Most or our OBL and Pulsafeeder metering pumps can be constructed from a range of heat resistant materials and several can withstand temperatures of up to 370 oC.

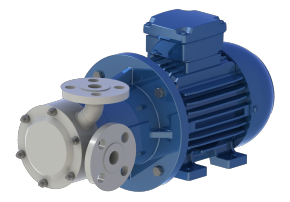

We have three ranges of heat resistant vane pumps: SNP, SVM and P Series.

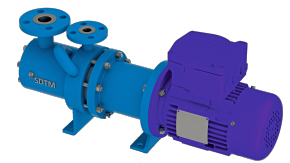

Our STM range of turbine process pumps can pump liquids with temperatures up to 300 oC.

We have three ranges of metallic gear pumps which can handle temperatures of up to 260 oC