WHAT DO BLACKMER MANUFACTURE

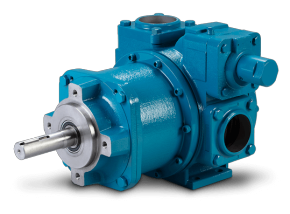

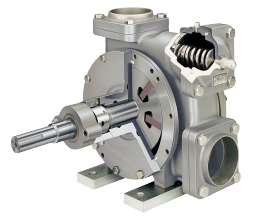

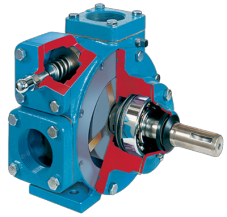

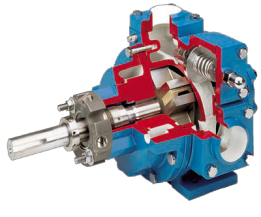

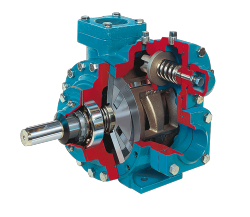

Blackmer manufactures sliding vane pumps based on a unique sliding-vane design which is now the recognised as the world-leader for handling industrial process fluids, Volatile or Organic Compounds, abrasive slurries and viscous liquids. Blackmer positive displacement pumps have revolutionized the pumping industry with their unique sliding vane technology. This revolutionary rotary vane design allows the pumps to self-adjust for wear to help maintain flow rates. This sliding vane pump design creates excellent self-priming and dry-run capabilities, while also providing sustained performance and trouble-free operation.

Each revolution of a Blackmer sliding vane pump displaces a constant volume of fluid. Variance in pressure has minimal effect. Energy-wasting turbulence and slippage are minimized and high volumetric efficiency is maintained.

Secondly, the gas comperessors by Blackmer have been helping customers optimize productivity and profitability while improving safety and environmental protection in the global chemical process, energy, transport, military & marine, general industrial, oil & gas, and food & beverage markets.

The single and two stage reciprocating gas compressors create a low-pressure area in the pumping chamber when the piston moves from the highest point of the stroke to the lowest point. Gaseous product (at a higher pressure in the tank) moves into the pumping chamber of the gas compressor. This volume of gas is then displaced when the piston moves to the top of the stroke. Equipped with high efficiency valves, ductile iron pistons, self-adjusting piston rod seals and other robust features, these reciprocating gas compressors are designed to provide maximum performance and reliability under the most severe service conditions. They are also a critical component in the design of oil and gas vapor recovery units (VRUs).

WHAT MAKES BLACKMER PUMPS SPECIAL

Blackmer offer the best combined characteristics of sustained high level performance, energy efficiency, trouble-free operation and low maintenance cost. Blackmer pumps are widely used by the U.S. defence agencies, and have long been the preferred technology for transfer, transport and delivery of petroleum products and liquefied gases.

Blackmer is the leading global provider of innovative, high-quality sliding vane pump, internal gear pump centrifugal pump, screw and regenerative turbine pump, and reciprocating gas compressor technologies for the safe transfer of liquids and gases. Since 1903, Blackmer pumps and compressors have been helping customers optimize productivity and profitability while improving safety and environmental protection in the global chemical process, energy, transport, military & marine, general industrial, oil & gas, and food & beverage markets.

For over 115 years, Blackmer has provided unparalleled product performance, superior service and support, innovation, and a commitment to total customer satisfaction. Learn more about how Blackmer is passionately committed to innovative technologies that positively impact the world, and why organizations everywhere know that to trust their job is completed correctly, they "Better Get Blackmer"!

How Rotary Vane Pumps Work How twin screw pumps work. How triple screw pumps work.

Click on the following link to take a look at the importance of Vanes in Rotary Vane Pumps - https://youtu.be/AV1JKW-3n_Q