WHAT DO ARGAL MANUFACTURE

Argal maufacturers both pneumatic and centrifugal pumps.

Diaphragm Pumps

Double diaphragm pumps or compressed air metering pumps for moving chemical, viscous, abrasive liquids, with solids or neutrals, even in hazardous areas (ATEX). They are anti-stall, submersible and run dry. Easy installation and maintenance.

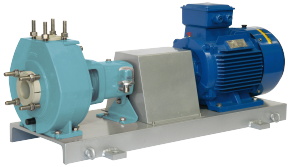

CENTRIFUGAL PUMPS

Horizontal or vertical, self-priming or submersible, centrifugal pumps are made of thermoplastic materials or fiberglass to transport the most aggressive and corrosive liquids. They can be used as process pumps for primary applications or service pumps for auxiliary services.

Vertical centrifugal pumps

KGK and Equipro range of Argal vertical sump pumps have column and volute casing submerged in the liquid while motor, its support and delivery pipe are assembled to the common base plate which rests on top of the sump well above of the liquid.

SELF-PRIMING PUMPS

The range of self priming pumps manufactured by Argal is made up by two magnetic drive models named TMA and by three mechanical sealed models named ZMA.

Magnetic drive pumps TMA are manufactured with GFR-PP (Glass fibre reinforced polypropylene) or flour polymer fluorinated CFFC E-CTFE+C(Carbon fiber filled Etylene-ChloroTriFluoroEtylene).

The innovative design of these magnetic drive pumps delivers more suction lift in less time making possible to prime what was not before to conventional self priming centrifugal pumps.

Mechanical sealed pumps ZMA are machined from blocks either in PP, PVCor PVDF material.

Argal’s invention consists of a turbo pump capable to prime from an empty suction pipe without foot valve by a biphasic operation delivered by the special configuration of the impeller rotating within a purposely designed stator casing.

The biphasic radial turbo pump is capable to self prime from higher suction height, higher density or higher vapor tension liquids within a lesser priming time than any conventional self priming pump.

what makes argal special

ARGAL boasts forty years of activity in the invention and production of pumps made of thermoplastic material, compounds, and corrosion-resistant metal alloys. During the past decade, significant efforts were directed to research and development on the entire production and such an effort resulted in entirely new or renovated pump ranges.

Their mission is a continuous and constant technological improvement along the path of innovation instead of emulation. How? By offering the best technical results obtaining the leadership in performance while providing appropriate responses to the needs of market dynamics throughout the “State-Of-The-Art” quality.

WHY BUY ARGAL PUMPS FROM AXFLOW

Argal boasts forty years of activity in the invention and production of pumps made of thermoplastic material, compounds and corrosion-resistant metal alloys.

During the past decade, significant efforts were directed to research and development on the entire production and such an effort resulted in pump ranges entirely new or renovated both regarding mechanical and hydraulic systems.

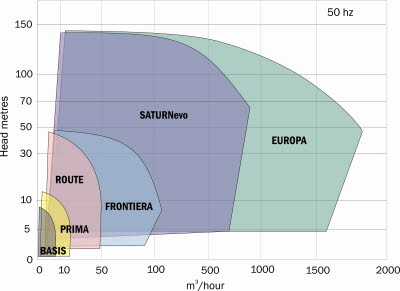

Today the company has an extensive range of pumps in various constructions for industrial applications requiring temperatures ranging from -40°c to +120°c with load capacities up to 1700 m3 /h and head over 100 m. Watch videos for explaination on the functioning of ARGAL Pumps.

For more information click here to visit our microsite on just ARGAL Pumps.

Argal Horizontal Pumps