Hygienic AODD Pumps

Hygienic AODD pumps designed and built with materials suitable for food production in mind

Air-Operated Double Diaphragm (AODD) pumps are a popular choice for hygienic applications in industries such as food and beverage, pharmaceuticals, cosmetics, and biotechnology. These pumps use compressed air to move fluids, making them ideal for handling delicate, viscous, or abrasive products while maintaining strict hygiene standards. Their ability to run dry, self-prime, and handle a variety of fluids without contamination makes them indispensable in sanitary environments.

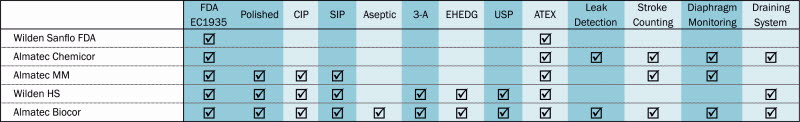

We have three main ranges of sanitary AOD pumps that cover all of the possible requirements of food and beverage production. AOD pumps are well suited as sanitary pumps as they offer a gentle pumping action, the ability to pump solids, can handle viscous products, are chemically resistant for CIP processes.

Features of hygienic aodd pumps

Hygienic Design

- Food-Grade Materials: AODD pumps for hygienic applications are constructed using FDA-approved, food-grade materials like 316L stainless steel and sanitary-grade elastomers (such as EPDM, PTFE, and Viton®) that ensure safe and sanitary fluid handling.

- Smooth Internal Surfaces: The interior surfaces of the pump are polished to a high degree of smoothness to minimize crevices where bacteria can harbor, making them easy to clean and reducing contamination risks.

- No Product Contact with Moving Parts: The fluid is entirely contained within the pump's diaphragms and valves, so it doesn’t come into contact with the pump's mechanical components, ensuring safe, contamination-free transfer.

Gentle Product Handling

- Low Shear Force: The gentle diaphragm movement creates a smooth and steady flow with minimal shear, which is essential for preserving the quality and consistency of delicate fluids like creams, emulsions, and biological materials.

- Solid Handling: AODD pumps can move fluids containing soft solids or particulates, such as fruit pieces in yogurt or solids in slurry, without damaging the product or clogging the pump.

Versatility

- Wide Range of Viscosities: AODD pumps can handle liquids of varying viscosities, from thin fluids like water or juices to thick and viscous substances like honey, syrups, or pastes.

- Self-Priming and Dry-Run Capabilities: AODD pumps are self-priming, meaning they can start pumping fluids without being manually primed. They can also run dry without damaging the pump, which adds flexibility and safety in operations where fluid supply might be intermittent.

- Air-Operated: Since AODD pumps are powered by compressed air, they can be used in environments where electricity might pose a safety risk, such as in wet or hazardous areas.

Performance and Efficiency

- Accurate Flow Control: The air supply to an AODD pump can be easily adjusted, allowing for precise control over the flow rate, making these pumps highly effective for dosing and metering applications.

- Leak-Free Operation: With no mechanical seals or packing, AODD pumps have a leak-free design, eliminating potential failure points that could lead to contamination or product loss.

- Efficient Pumping: AODD pumps can efficiently move both low- and high-viscosity fluids over a wide range of pressures, making them suitable for various hygienic applications.

Cleanability and Maintenance

- CIP/SIP Compatibility: Hygienic AODD pumps are designed to be compatible with Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems, allowing for thorough cleaning and sanitization without the need for disassembly. This ensures that the pumps meet the stringent cleaning standards required in hygienic industries.

- Easy Maintenance: These pumps have a simple design with fewer moving parts compared to other pump types, which simplifies maintenance. Diaphragms and valves are easily replaceable, and there’s no need for lubrication or complex mechanical seals.

- Corrosion Resistance: Constructed from corrosion-resistant materials, AODD pumps are durable and resistant to the chemicals used in cleaning and sterilization processes.

Benefits of hygienic aodd pumps

- Contamination-Free Operation: The fluid being pumped only comes into contact with the pump’s diaphragms and wetted parts, reducing the risk of contamination and making AODD pumps ideal for hygienic applications.

- High-Pressure Handling: AODD pumps can generate high pressures, making them suitable for moving thick, viscous products or pumping fluids over long distances.

- Versatile Fluid Transfer: From delicate, thin liquids to abrasive or high-viscosity products, AODD pumps can handle a wide variety of fluids, offering unmatched flexibility in the types of products they can transfer.

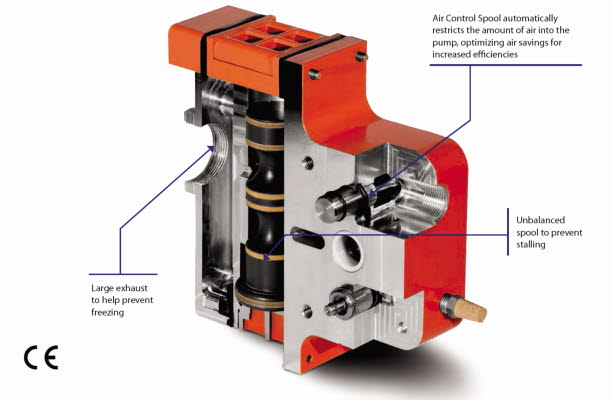

Wilden Pump Pro-Flo SHIFT

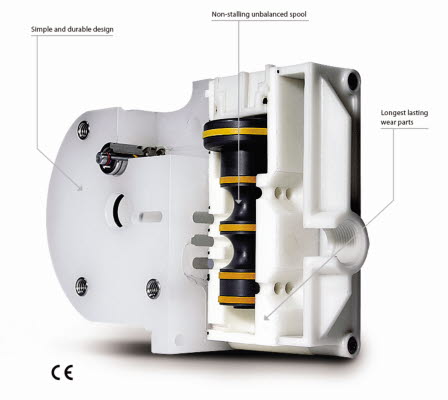

Wilden Pro-Flo® SHIFT Series pumps set the standard for AODD pump performance, providing increased energy savings and higher flow rates when compared to many competitor pumps.

Read about Wilden Pump Pro-Flow SHIFTWilden Pump Pro-Flo

As the industry's workhorse, the Wilden Pro-Flo® Series combines elegant simplicity with robust and reliable performance that end users have come to depend on for more than 20 years.

Read about wilden pump pro-floAlmatec Accessories

Almatec pumps boast an impressive range of integrated optional accessories.

read more about almatec accessoriesWilden Pump Repair Service

AxFlow offer a professional and documented Wilden Pump Repair Service that only uses original Wilden spare parts.

Read more about Wilden pump repair service