AxFlow supply a range of Pumps for high viscosity fluids. Our high viscosity pump range includes AODD, Eccentric disc, centrifugal and many more.

The definition of viscosity changes from industry to industry, the viscosity of individual liquids generally changes with temperature. Viscosity is the property of a given liquid that describes its resistance to flow. A highly viscous fluid tends to be thick, like honey or cold maple syrup. Compared to a relatively nonviscous fluid, such as water, highly viscous liquids flow much more slowly. Of course, when you add energy, in the form of heat, the molecules making up these liquids become less densely packed and are better able to slide past one another. Thus, honey becomes much less viscous when it’s hot than when it’s cold.

Here are the typical maximum viscosties of most common pump types.

| AODD | 20,000 cP |

| Centrifugal | 200 cP |

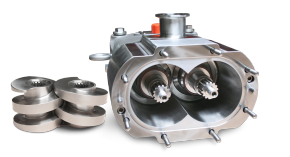

| Circumferential Piston | 1,000,000 cP |

| Eccentric Disc | 3,000 cP |

| Gear | 1,000,000 cP |

| Metering | 5,000 cP |

| Peristaltic Hose | 25,000 cP |

| Peristaltic Tube | 10,000 cP |

| Rotary Lobe | 700 cP |

| Rotary Vane | 22,000 cP |

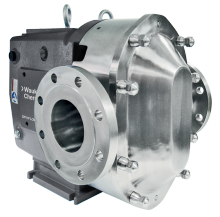

As the density and thickness of a fluid increases, it becomes increasingly difficult to flow and pump with a centrifugal pump. Typically the thicker the fluid a different technology is required being positive displacement pumps, as with a centrifugal pump the thicker the fluid is the more it recirculates within the pump head.

Pumps which handle high viscosity fluids typically have larger inlets, run slower, and are consequently more efficient with such fluids than a centrifugal pump. Pumping high viscosity liquids require careful handling to prevent changes to its consistency, ensure parts of the liquid do not separate out and that solids remain in suspension.

The secret to handling viscose fluids sucessfully is a wide range of pump types something that AxFlow has in abundance.These are supported by our UK and international expertise and ability to measure fluid viscosities with our rheometer.

We are also able to supply systems that incorporate mechanical pump feeders and bridge breakers.

Why is viscosity an important factor when selecting a pump

Viscosity is an highly important factor to consider when selecting a pump because it directly affects the pump's ability to efficiently transport liquids or fluids.

- Pump Performance: The viscosity of the fluid being pumped can significantly impact a pump's performance. Different pump types are designed to handle fluids with specific viscosity ranges.

- Cavitation Risk: High-viscosity fluids can increase the risk of cavitation, which occurs when the pressure in the pump drops to a level where the fluid vaporizes and forms cavities or bubbles.

- Pump Type and Design: Different types of pumps are better suited for handling fluids with specific viscosities.

- Maintenance and Longevity: The viscosity of the fluid can also impact the wear and tear on pump components. High-viscosity fluids may cause more significant wear on impellers, seals, and bearings, potentially leading to increased maintenance requirements and shorter pump lifespan.