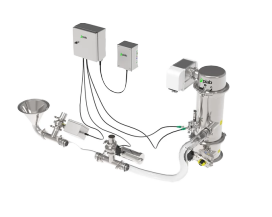

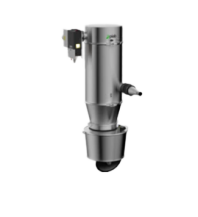

Piab Vacuum conveyors use their patented COAX venturi cartridge system to generate vacuum by utilising compressed air to transfer material from a feed source the desired discharge point.

Vacuum conveyor

6 series from 1 manufacturers

WHAT IS A VACUUM CONVEYOR?

A vacuum conveyor is a compressed air system utilized to transfer dry materials from a feed source the desired discharge point in a factory by the use of suction. The material, usually consisting of powders, pigments, granules, tablets, capsules, small parts, is conveyed in a tubing system from point A to B.

The working principle of a vacuum conveyor

The pressure differential is generated by creating a vacuum, where material will be “carried” by the air flow caused by the vacuum. This mechanism works best with any dry free flowing materials. Should a material be more challenging in its handling characteristics, we also offer a solution to transfer materials with bridging. Vacuum conveyors are ideal for both small and larger applications, where bulk material is fed to the conveyor from big bags, sacks, hoppers, railcars, silos, and other typically dusty containers. They are inherently self-cleaning, have a smaller footprint than other traditional conveyor options, are easy to install, and are energy efficient. They come with the option to be driven by compress air through our conventional vacuum pump or if compressed air is at a premium we also have the option to supply an electro-mechanical vane pump.

Vacuum conveying principle video

Why buy Vacuum conveyors from AxFlow?

AxFlow offers Vacuum conveyors for the widest range of industries and applications. Only at AxFlow do you receive individual advice from industry-experienced process engineers and the manufacturer-independent selection of the world's leading process technology. Do you need support in selecting the equipment for your needs? Do not hesitate to get in touch. AxFlows' experts and engineers can provide guidance for selecting, specifying, installing, and maintaining your equipment.