Cleaning solutions by System Cleaners

Achieving an ideal balance between maximizing production time and achieving optimal cleaning poses a challenge for food and beverage processors. To expand market share and uphold a favourable brand reputation, it is crucial to establish a clean and safe processing environment that mitigates any potential irregularities in the final product that could jeopardize consumer safety or harm your brand image.

To guarantee this, it is necessary to thoroughly clean and sanitize all surfaces within the processing area, including floors, walls, processing equipment, utensils, and more, at regular intervals. This proactive measure aims to prevent bacterial growth and minimize the risk of cross-contamination between batches, thereby ensuring product integrity and upholding stringent quality standards.

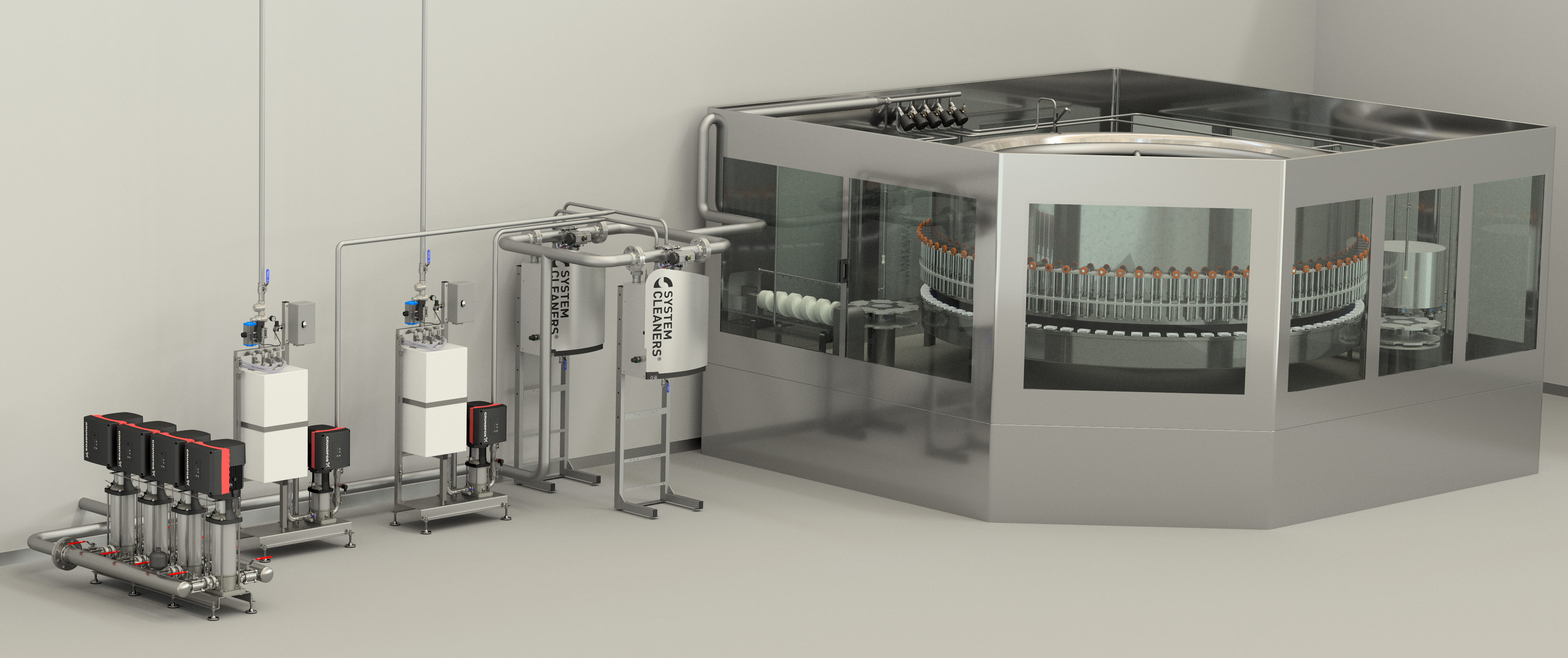

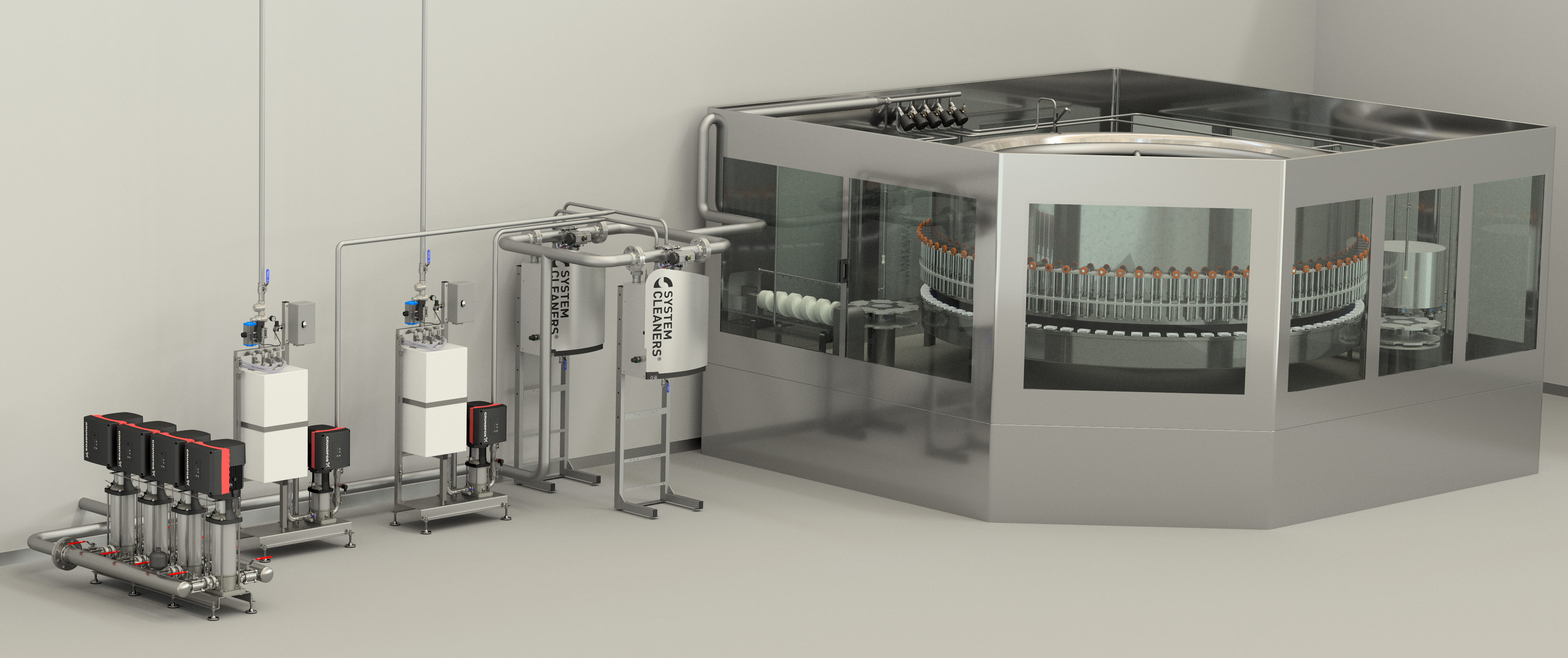

AxFlow, in collaboration with System Cleaners, provides a range of open plant cleaning solutions, including automated, manual, and mobile options. The solutions draw on three decades of valuable expertise gained from the food and beverage industry. Designed and manufactured in Denmark, they prioritize maintaining superior hygiene standards and food safety. By incorporating advanced surface cleaning technology and robust, dependable systems of exceptional quality, System Cleaners solutions ensure the efficiency of your cleaning operations for years to come.

Sometimes a standard cleaning solution suffices, while other situations call for a customized approach. The crucial factor lies in ensuring that the chosen solution aligns precisely with your unique requirements and challenges.

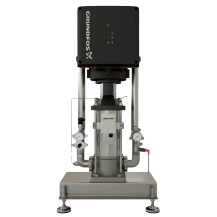

Automated cleaning solutions

Integrating an automated solution on your processing equipment means that every single surface, as well as the peripheral areas and ‘dark spots’, is cleaned during each cleaning cycle. Nozzle bars placed in strategic places and customized to match the equipment will ensure a consistent cleaning result every time.

Benefits of automated cleaning:

Benefits of automated cleaning:

-

Optimization of food safety and hygiene

-

Reduced cleaning time → increased production time → increased output

-

Reduced water and chemical consumption and overall operational costs

-

Increased employee safety

-

Extended shelf-life

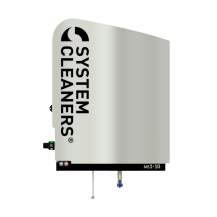

Manual cleaning solutions

Our manual open plant cleaning solutions assist you in optimizing hygiene and food safety, and they offer a high degree of flexibility in e.g., the choice of equipment, number of users and functionalities. The wide range of products for manual cleaning in our portfolio ensures that no matter what challenge you face, we can find a solution for it.

Benefits of manual cleaning:

-

Up to 4 chemical inlets on the workstations

-

Option of concentrated or prediluted chemical supply – or both

-

Hygienically designed equipment

-

User-friendly operation and service

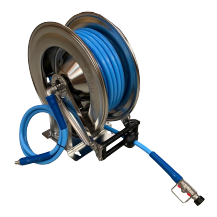

Mobile cleaning solutions

With a mobile open plant cleaning solution, you can benefit from a high degree of flexibility without having to invest in a more extensive solution.

We offer a wide range of options so you can find the solution that matches your needs.

Benefits of mobile cleaning:

Benefits of mobile cleaning:

-

A high degree of flexibility in terms of coverage

-

Improved levels of hygiene and food safety

-

Low-pressure technology ensures effective cleaning with reduced water and chemical consumption

-

A less extensive investment than fixed installations

Automated solutions for a wide range of applications

If you have a challenge in your food or beverage processing plant on a specific piece of processing equipment, our skilled team of engineers and solution architects can help you create a cleaning solution that matches that equipment, making sure that ‘the dark spots’ are cleaned, and the level of hygiene and food safety is maintained.

Each solution is comprised of a range of modular elements combined into a complete system covering the surfaces of the application.

A selected list of application options:

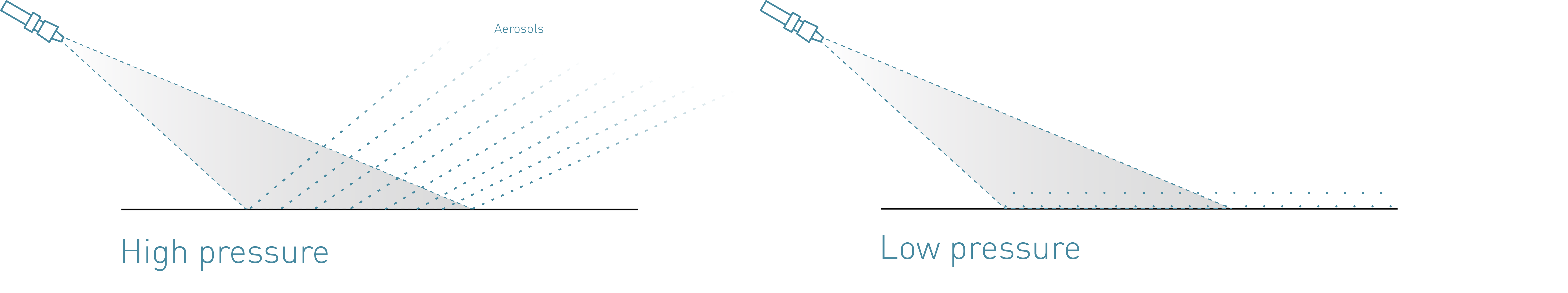

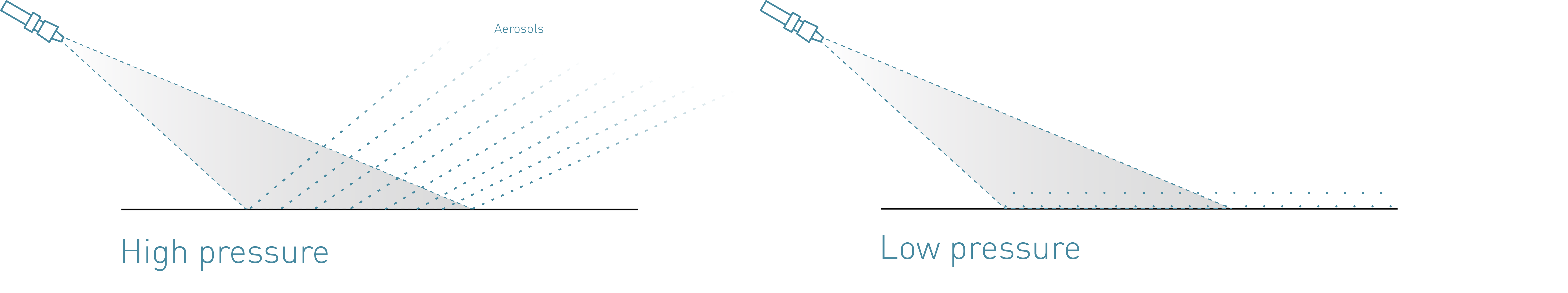

better hygiene with low-pressure technology

Studies show that low-pressure with boosted water is the superior technology for cleaning surfaces in the food and beverage industry compared to high-pressure. These are just some of the parameters:

-

Higher rinse impact

-

More effective removal of residues

-

Lowest temperature drop

-

Reduced risk of cross-contamination

-

Improved working environment

The perfect combination of the correct temperature and volume of water in interaction with chemicals means that a System Cleaners solution is optimised for cleaning the surfaces in all types of food and beverage processing facilities contaminated with fat, bacteria, yeast, microbes, limescales and other deposits. This way all surfaces are not only visually clean, but also bacteriologically clean.

Benefits of automated cleaning:

Benefits of automated cleaning:

Benefits of mobile cleaning:

Benefits of mobile cleaning: