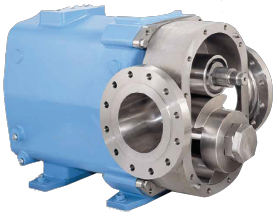

Circumferential piston pumps are a type of positive displacement pump. They use interlocking, arc-shaped rotors to move fluid smoothly and efficiently through the pump chamber without direct contact. This design minimizes mechanical shear and damage to the fluid, making these pumps ideal for handling both low and high-viscosity fluids. The rotors maintain close clearances, which, coupled with their unique geometry, lead to high operational efficiency and low slippage, even under pressure surges.

Circumferential Piston Pumps

6 series from 1 manufacturers

-

- Acetate

- Adhesives

- Agriculture

- Bakery and confectionery

- Beauty & Personal Care

- Brewing and beverages

- Building Services

- Chemical

- Convenience food

- Dairy

- Detergents

- Dye & Pigment

- Emulsions

- Fish Farming

- Food & Beverage

- Fruit Concentrates

- Meat Processing

- Oil & Gas

- Oil Fats & Mayonnaise

- Paint & Surface Coating

- Paints & Resins

- Paper Mills

- Pet Food

- Pharmaceutical

- Plastic

- Refineries

- Research & Development

- Sugar Processing

-

- Analysis

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dual Dispensing

- Feed

- Filling

- Filtration

- Flow Control

- Greasing

- Grinding

- Handling

- Heating

- High-Pressure

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Off-loading

- Powder Coating

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Rinsing

- Sampling

- Settling

- Spraying

- Tempering

- Transfer

- Treatment

- Unloading

- Volumetric Dispensing

- Washing

- Water-Jet Cleaning

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Ammonia

- Beer

- Biological Broths and Slurries

- Caustic Solutions

- Cereals

- Chocolate

- CIP Fluids

- Clay

- Coffee

- Dairy Products

- Detergents

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- High Viscosity Liquids

- Hygienic Liquids

- Lake Water

- Latex

- Low Viscosity Liquids

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Produced Water

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Synthetic Fibers

- Thixotropic Fluids

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Water

- Wine

- Wort

-

- Abrasion Resistant

- Adjustable-Flow

- Aseptic

- Automatic

- Canned

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Mobile

- Modular

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Self-priming

- Single-Stage

- SIP

- Solids Handling

- Variable Speed

- Vertical

- Vertical-Mount

How Circumferential Piston Pumps Work

The circumferential piston pump is a compact unit that uses the same operating principle as the rotary lobe pump, whereby interlocking rotors move a fixed volume around the pump chamber. Where they differ is in the shape of the rotors, which in the case of the circumferential piston pump are arc shaped. The arc-shaped rotary pistons, or “wings”, have large heads which follow the profile of the pump body and travel in annular-shaped cylinders machined in the pump body. They also utilise a ‘rotor hub’ on the pump body which drives the rotary pistons on independently rotating shafts. Timing gears create a low-pressure cavity at the inlet side that helps introduce fluid into the pump.

These features result in a much longer sealing path between the rotor and the pump body. The long sealing path reduces slippage and produces a smooth product flow without destructive pulses or pressure peaks, and without the need for valves or complex parts. The long sealing path also ensures virtually no back slippage of liquid, making their accuracy as high as 2-3%.

Furthermore, the large fluid cavities of the rotors and the generously sized anti-cavitation ports allow for efficient pumping of high viscosity fluids, slurries, and even liquids containing large chunks or particles.

Advantages of Circumferential Piston Pumps

- Efficiency and Precision: These pumps are known for their precise metering capabilities and high efficiency due to a long sealing path that reduces back slippage.

- Gentle Handling: The interlocking rotors provide a pulse-free pumping action, ideal for sensitive and viscous fluids.

- Versatility: They can handle a wide range of fluids, including those with large particles, thanks to their large fluid cavities and anti-cavitation ports.

- Durability and Low Maintenance: The design minimizes wear on the pump by avoiding direct contact between rotors and the pump housing, extending the pump’s lifespan and facilitating easy maintenance.

- High Performance: Suitable for high-pressure applications and offers bi-directional flow, making them adaptable to various industrial processes.

Applications of Circumferential Piston Pumps

Circumferential piston pumps are extensively used in industries requiring high standards of hygiene and efficiency, such as:

- Food and Beverage: Handling dairy, confectionery, and sauces without degrading the product quality.

- Personal Care and Pharmaceuticals: Ensuring gentle handling of creams, gels, and medicinal ingredients.

- Industrial Applications: Effective in pumping slurries and pastes in paper production, ceramics, and chemicals.

Their ability to maintain the integrity of processed materials while ensuring efficient operation makes circumferential piston pumps a preferred choice in both sanitary applications and challenging industrial environments.

Why buy circumferential piston pumps from AxFlow?

AxFlow provides circumferential piston pumps that cater to an extensive variety of industries and applications. Exclusive to AxFlow, you will be provided with personalized recommendations from highly experienced process engineers, and access to the most prominent process technology manufacturers that are independent of the manufacturer. If you require assistance in selecting the appropriate pumps that satisfy your requirements, feel free to contact AxFlow without any delay. AxFlows engineers and specialists can help with the selection process, specifications, installation, and maintenance of your fluid handling equipment.